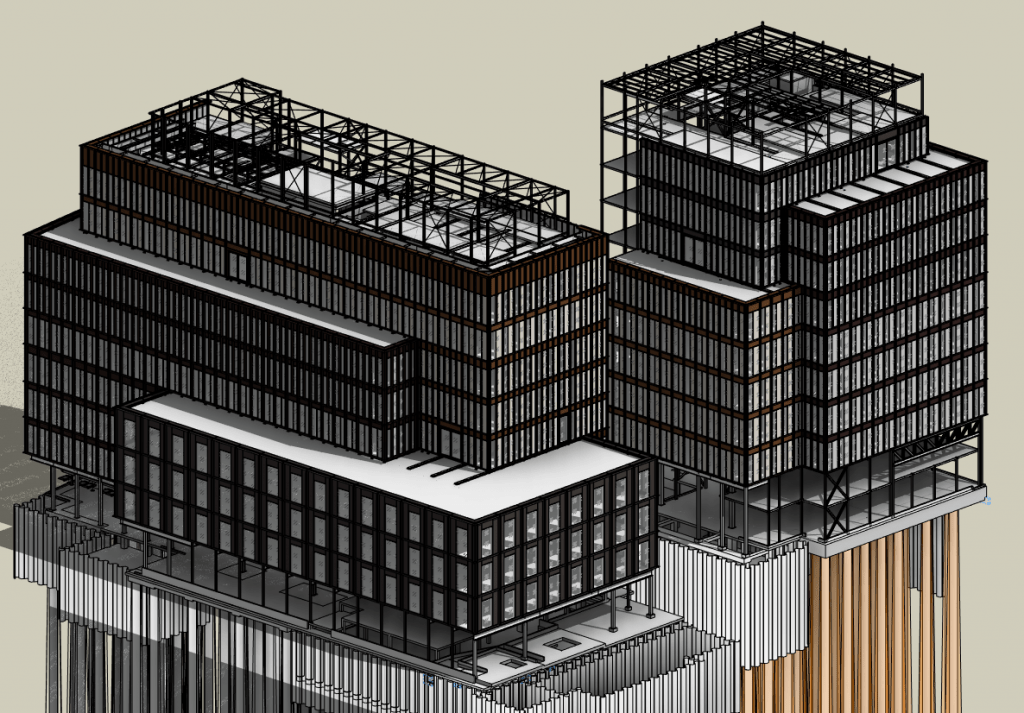

The Forge project is an excellent example of using advanced technology and Building Information Modeling (BIM) methodology to create an innovative facade for a building on Southwark Bridge Road. This project is not only groundbreaking in terms of sustainable solutions application but also a testament to how innovative design approach and software integration influenced the project’s success.

The main goal of The Forge project was to create a facade with a unique character that stands out in the Southwark Bridge Road landscape. More importantly, however, the project aimed to achieve sustainable and efficient solutions, both environmentally and economically. A significant objective was also to coordinate design activities with other industries, which had a substantial impact on the project’s success.

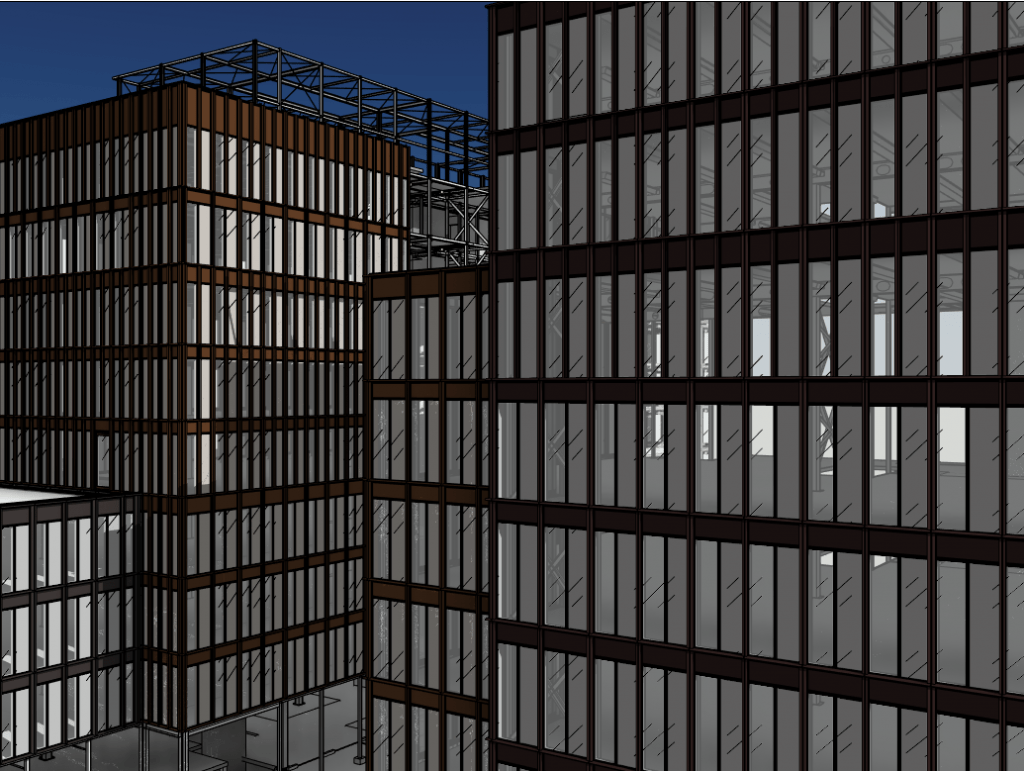

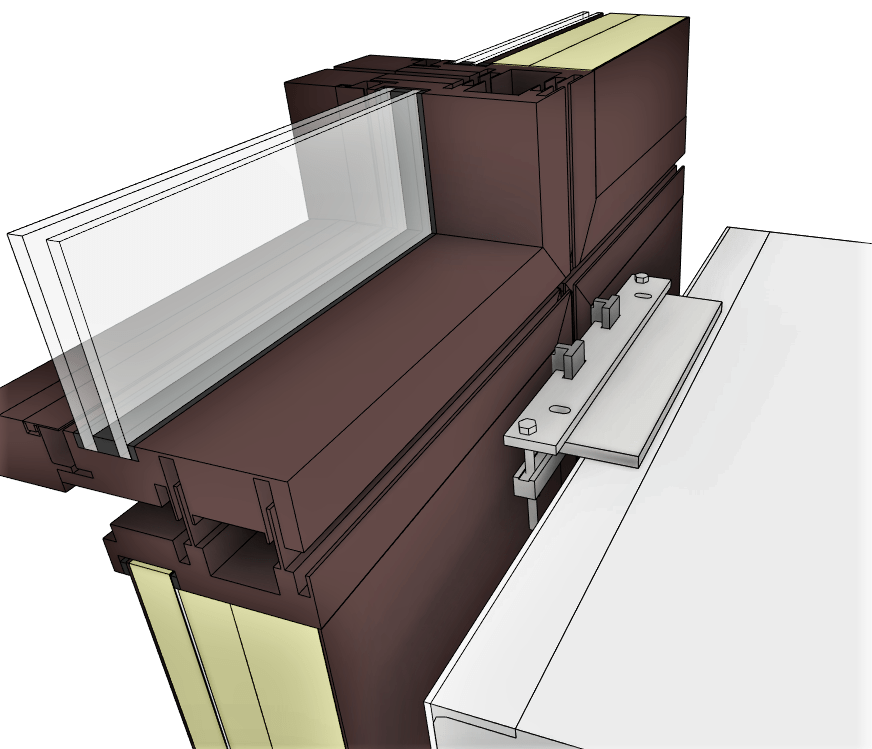

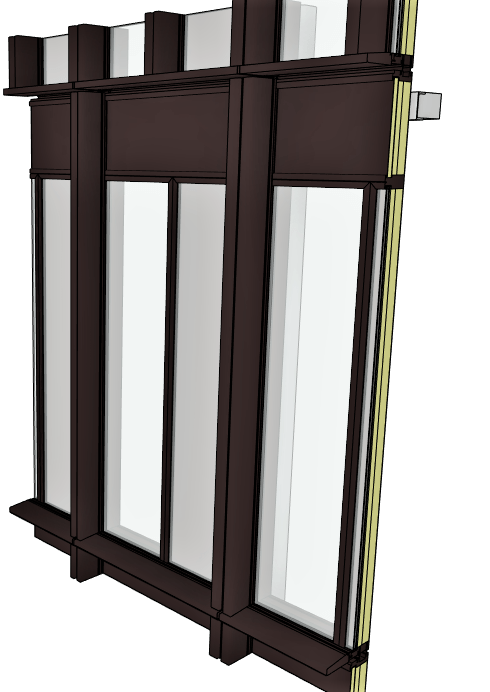

The Forge project is primarily distinguished by its facade. It features an elegant structure of vertical bronze fins that resonate with the historical bridges and walkways in the Southwark area. The BIM-based facade is an example of how innovative design solutions and software integration can create a work of art, combining aesthetics and functionality.

The Forge project utilized an integrated approach to design. Advanced BIM tools were used in the project, including software like Autodesk Revit, Inventor, and Solid Edge. This software integration allowed for comprehensive project management and enabled collaboration across different fields, contributing to the project’s coherence.

The Forge project is an excellent example of using Building Information Modeling and software integration to create an innovative facade and sustainable building design. It is also proof of how coordinated design approach and collaboration with other industries influence a project’s success. The Forge is an example of how advanced tools and technologies can revolutionize facade design and contribute to creating spaces that meet the highest standards of sustainable building, combining modernity with environmental care and user comfort.