For effective management and execution of construction projects, proper analysis before starting work is a key element.

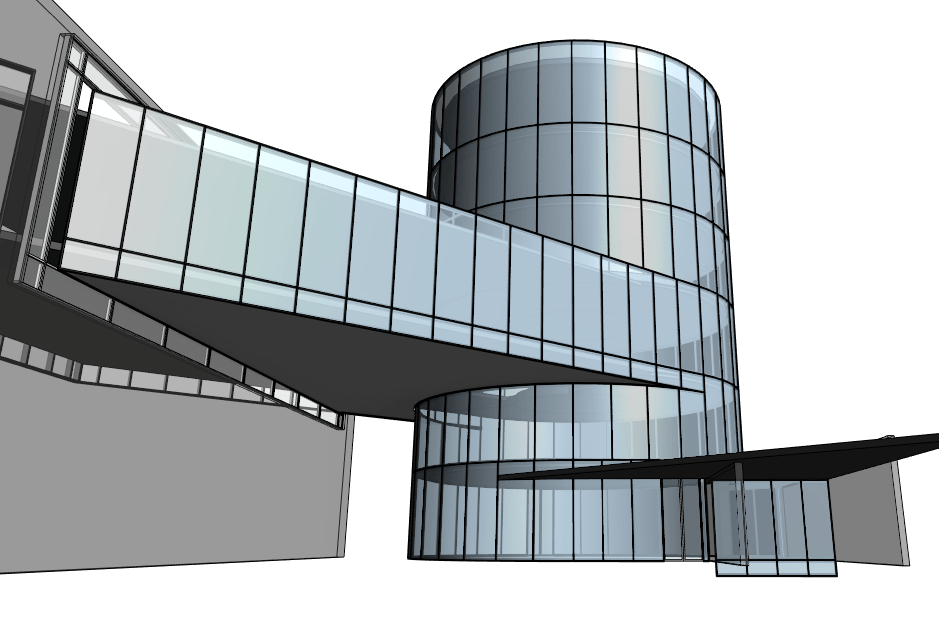

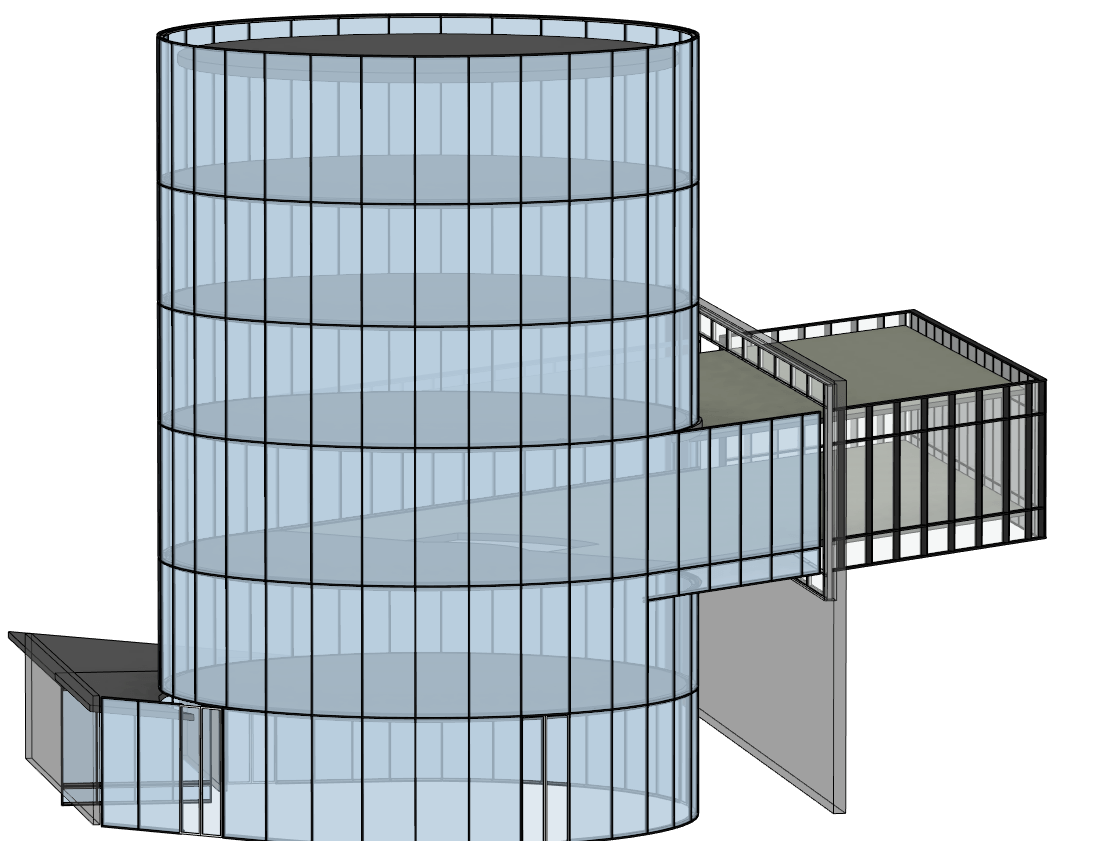

The Blackbird Airport Terminal in Billund is an excellent example of how advanced BIM tools can significantly impact the design process, as well as the efficiency and quality of the project work.

Defining Needs

At the beginning of the project, it is important to define needs and set goals.

For the Blackbird Airport Terminal, the priority was to ensure the most optimized design and production process possible.

By avoiding unnecessary interruptions to solve problems, smooth project progress can be achieved, while simultaneously avoiding the time loss that usually occurs while solving problems during the project.

3D Conceptual Modeling

In the Blackbird Airport Terminal project, we applied 3D conceptual modeling, which allowed us to detect potential hazards related to invisible places in the documentation before creating the executive design.

Thanks to this early analysis, we were able to solve problems and obtain approval of solutions without wasting time.

Many projects experience a longer halt waiting for problem resolution and approval by the appropriate institutions.

This valuable delay can be avoided, and the costs of “repairs” can be significantly lower if problems are resolved at the virtual stage.

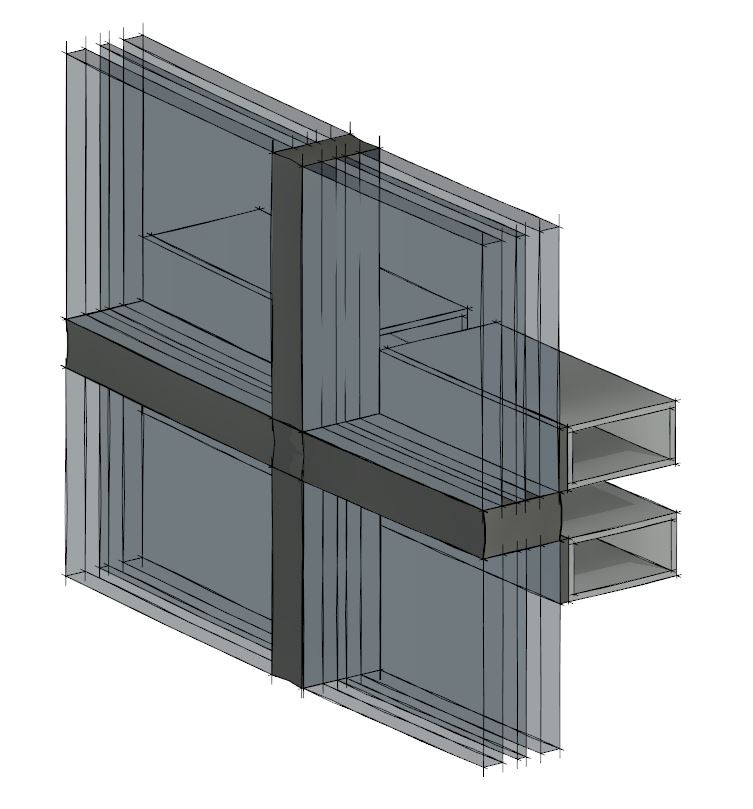

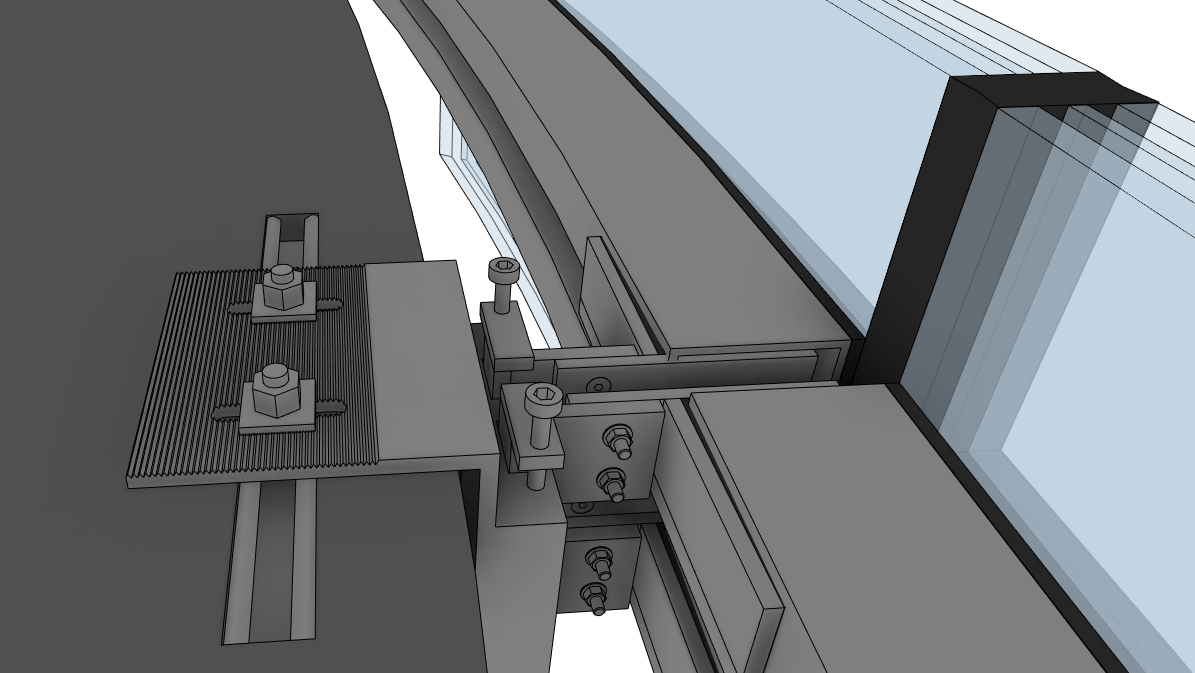

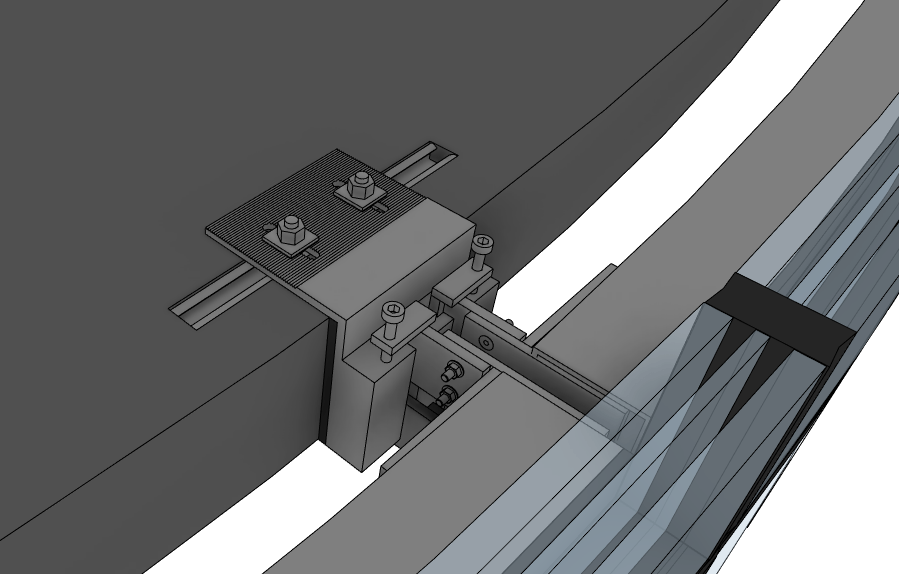

Geometry and Hazard Analysis

The task of the design team was to thoroughly analyze the geometry of the terminal’s glass facade.

Special attention was paid to the intersection points, which posed a significant design challenge.

2D documentation often does not allow for a full understanding and analysis of complex issues related to the building’s geometry.

The 3D model allowed for the identification of high-risk areas and their presentation to the system manufacturer and contractor to find optimal solutions.

Precision and Tolerances

Due to the specific nature of the concrete facade construction, it was necessary to precisely determine the execution precision and tolerances.

Combined with the characteristics of the work of aluminum profiles and glass, the proper mounting solution was defined, taking into account all potential hazards associated with facade production.

Conclusion

The Blackbird Airport Terminal project in Billund is an excellent example of how BIM modeling can impact the quality and efficiency of the design process.

Early detection of problems, elimination of unexpected delays, and optimized coordination of the design team are key elements of this success.

By using advanced modeling tools, not only was technical excellence achieved, but also time and cost savings related to the project.

Thus, the Blackbird Airport Terminal project in Billund has become a model of effective use of BIM technology in the construction industry.