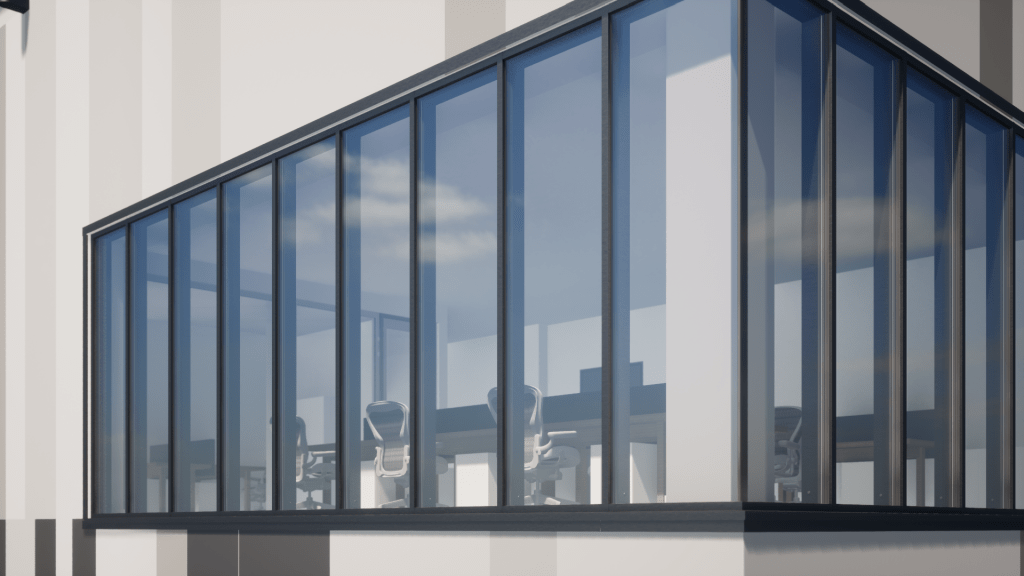

Creating a design in the form of 3D models allows us to avoid clashes and other problems on the construction site – we reduce the risk of very costly changes due to the need to modify the aluminium joinery. Moreover, we are able to assess the level of aesthetics and finish – even before production and assembly.

Delivering projects in BIM requires incredible team discipline and collaboration between multiple industry to achieve collective success. Delivering projects just-in-time enables periodic coordination and the elimination of issues. Fortunately, the issues arise earlier on the virtual site. By the time the physical execution takes place, the problem has already been solved.

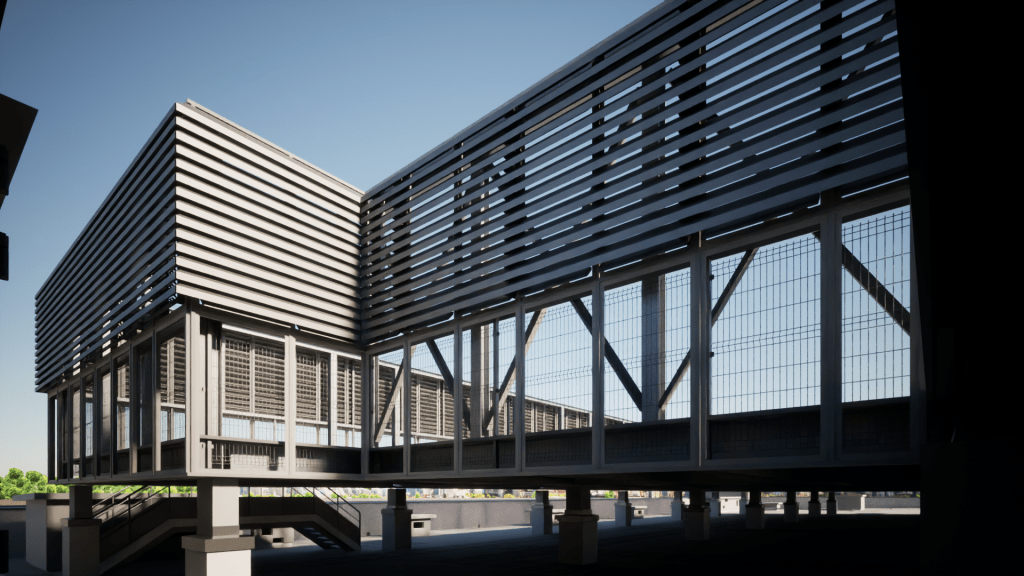

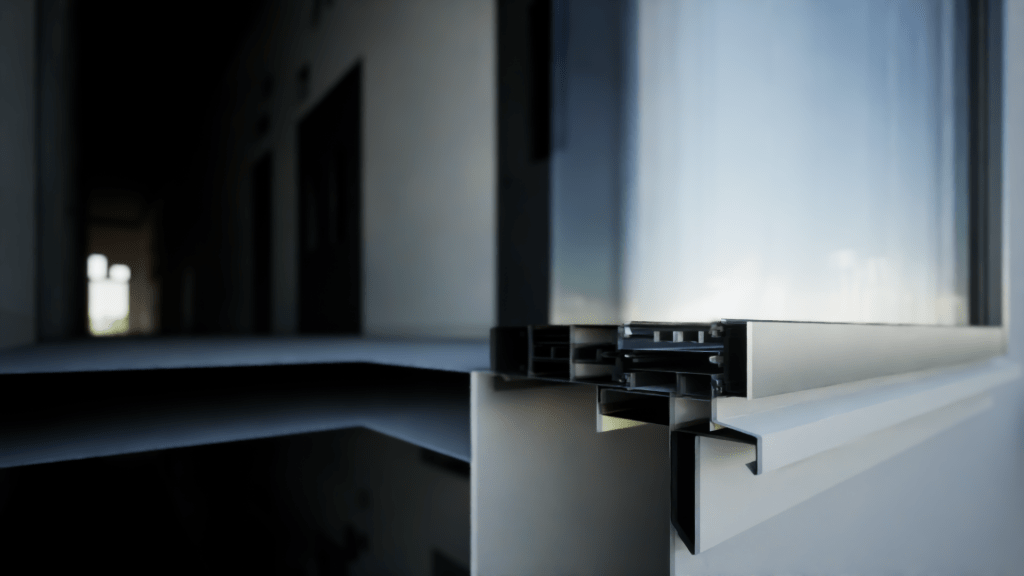

This time, we had the pleasure of supporting the aluminium facade design team in cooperation with the other members of the process. We performed a BIM model for them that suited the scope of the aluminium joinery – facades, windows, doors. Each component was unique in its form and required a different approach.

The high level of detail allowed us to accurately define the installation of façade elements, showed the problems associated with fixing to prefabricated elements. Thanks to the models, the analysis of the structure was simpler than in the case of 2D documentation, and the placement of fastening points could be done more efficiently – so as not to cause later problems – on the construction site.