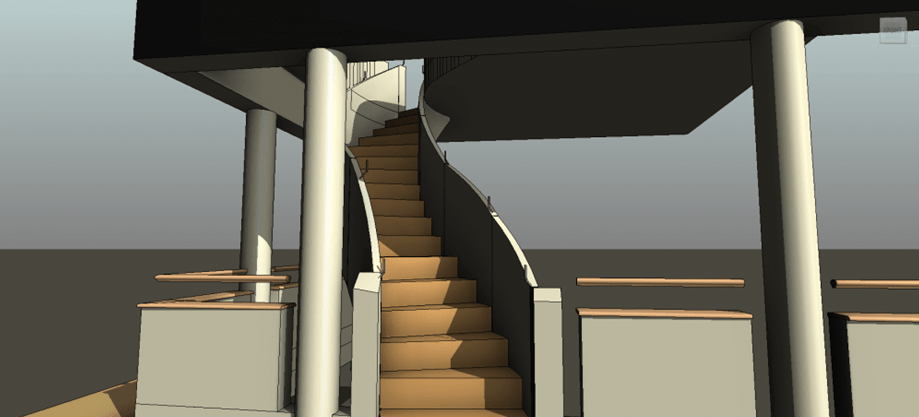

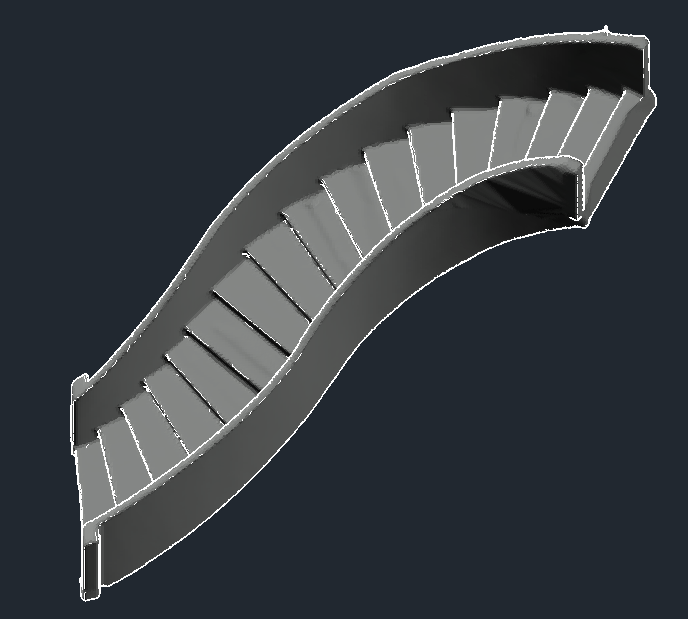

One of the tasks that our client faced was the finishing of a staircase in Iceland. The project involved making new handrails for a staircase with a highly advanced, non-linear geometry.

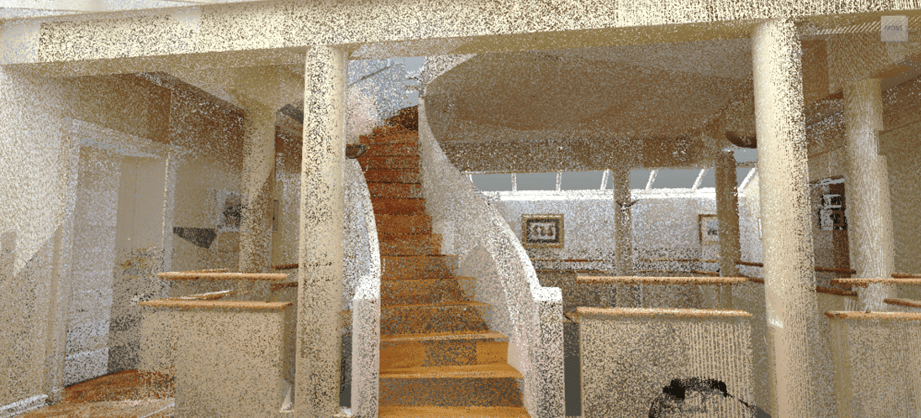

The location and the difficult shape of the staircase made it impossible to take measurements using the traditional method. In this case, it was decided to perform measurements by terrestrial laser scanning (TLS). This method allows for obtaining extremely accurate measurements in the form of a point cloud.

| These are data which represent a set of data points in space. These points can represent a shape or a 3D object. Each point position has its own set of Cartesian coordinates (X, Y, Z) Point clouds are usually created by 3D scanners or photogrammetric software that measure multiple points on the outer surfaces of objects in their vicinity. As a result of the 3D scanning process, point clouds are used for many purposes, including the creation of 3D CAD models of manufactured parts, for metrology and quality control purposes, and for many visualisation, animation, rendering and mass customisation applications. |

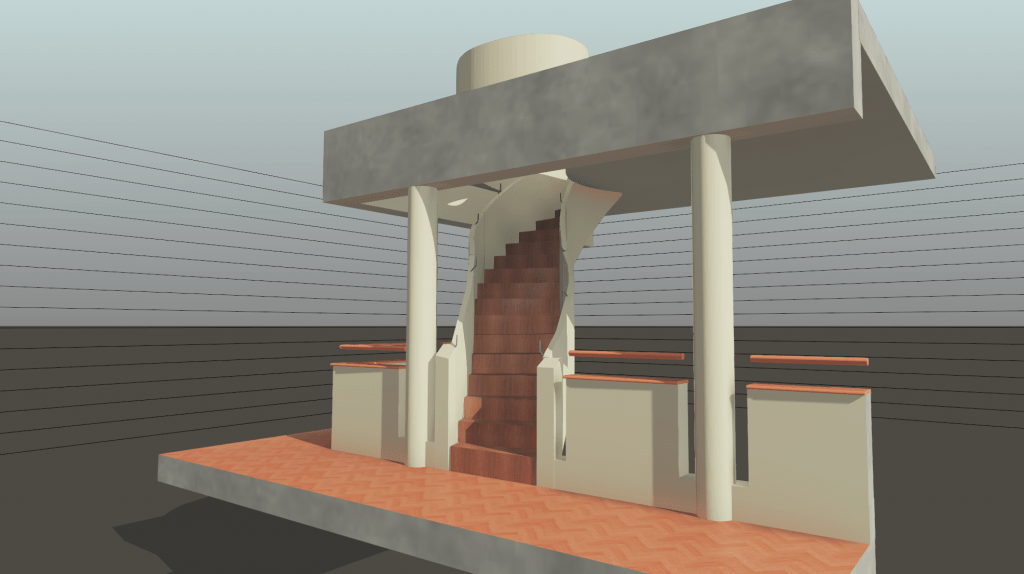

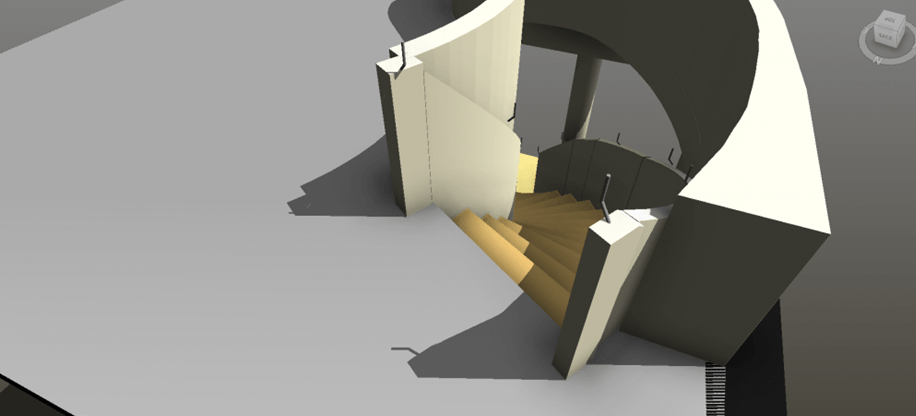

The measurement was integrated using Autodesk software. The resulting point cloud was used as a source to create a 3D model of the stairs, as well as reference points of the environment, which was the existing balustrade.

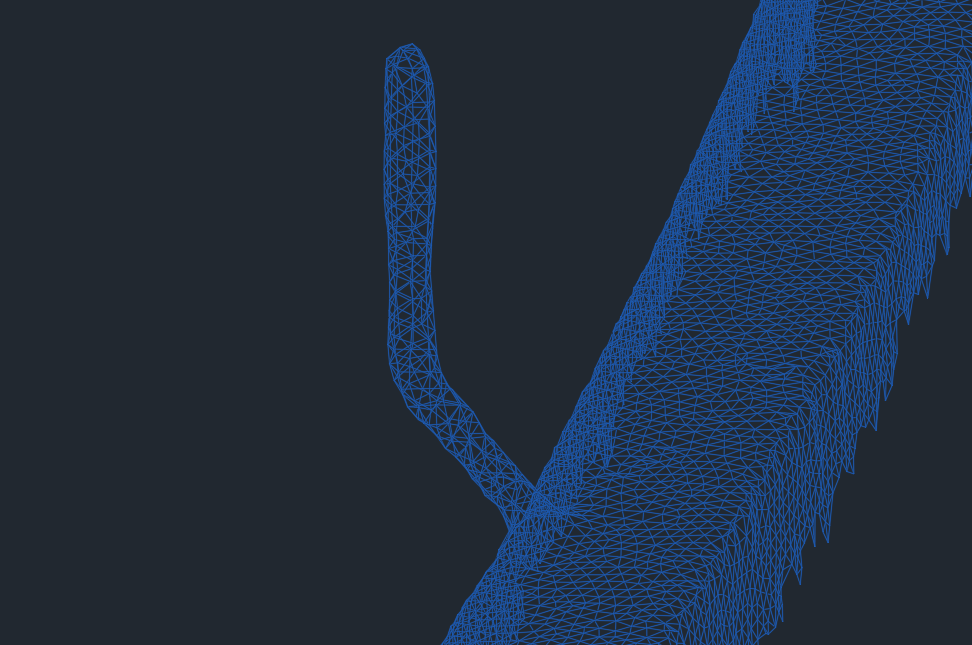

This model was created in such a way that the designer could comfortably make the project in CAD environment. The key points in this issue were the protruding brackets, which needed to be adjusted. For this purpose, a more finely structured model was made by creating a mesh and adapting it to the CAD environment.

The point cloud is also a good source for design interpretation. We can perform an analysis by placing the production models (CNC) in the project space and comparing it with the point cloud. This will allow us to check for collisions, manufacturing accuracy before transportation and assembly.