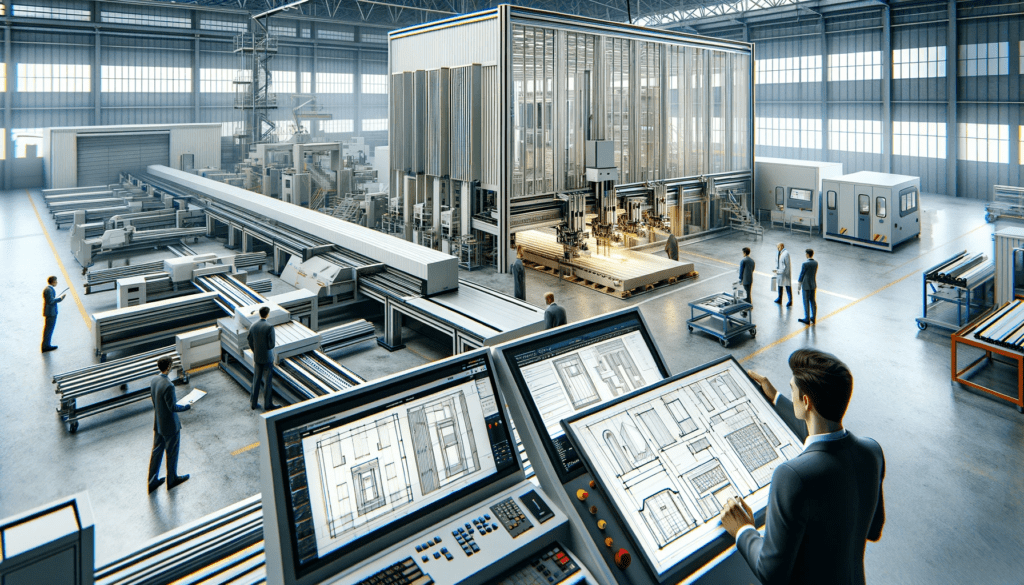

Creating production documentation is a key stage in the entire project cycle. It’s here that we transform ideas into concrete plans that are indispensable for manufacturers, installers, and other specialists involved in the facade implementation process.

Let’s walk together through the process that leads from concept to precise documentation, bringing you closer to its essence and uniqueness.

Ready? Let’s begin!

We Model Components of the Entire Facade

In the first step of the production documentation creation process, we model each element of the facade in full detail.

This means that for models intended for workshop production, we create virtual counterparts of each element that needs to be produced.

Our models are faithful representations of the actual facade components and do not have any simplifications in geometry.

As a result, we provide you with incredibly detailed documentation ready for production, ensuring precision and accuracy in every detail.

Virtually Assembling Facade Elements

The next stage of the process is the virtual assembly of facade parts.

Thanks to these assemblies, we can precisely check the fit of the holes and the compatibility of production elements before they are produced.

This step allows for the coordination of elements and preliminary checking of their interrelations, which translates into a smooth production and assembly process.

Compiling Elements Necessary for the Assembly of the Facade/Elements

Each facade project includes an assembly list that precisely describes all the elements needed to build the facade.

It is a comprehensive list, containing descriptions of individual parts and the quantities needed to perform the full range of workshop and assembly works.

Preparing Profile Cut Lists and Optimizing Their Use

A key part of any facade is the profiles.

Our task is to properly group these profiles according to catalog numbers and prepare a ready-made cut list from the manufacturer’s profiles.

Our solutions consider the optimization of profile arrangement, which allows for minimizing material usage and efficient production.

Creating Ready Drawings for Production and Generating Files in Ready Formats for CNC

At the end of the production documentation creation process, we deliver ready drawings that serve as the basis for production.

Parts that require workshop production are transferred in the form of models in formats dedicated to CNC milling. Additionally, we generate files in ready formats, tailored to production needs, to ensure the highest precision and effectiveness in the production process.

In this way, we guarantee that the facade project becomes a reality in accordance with the highest standards of quality and accuracy.

It is this comprehensive process of creating production documentation that allows transforming vision into reality and creating a facade that impresses both aesthetically and with technical precision.